After a long wait, the "New EU Battery Regulation" was finally officially published and took effect on August 17, 2023. The regulation aims to impose mandatory requirements on almost all types of batteries placed on the EU market, covering indicators such as lifecycle carbon footprint disclosure, sustainability, safety, due diligence, battery passports, and waste battery management, and defines the obligations and responsibilities of battery and battery product manufacturers, importers, and distributors.

Image from the European Commission's official website

The regulation will come into force on February 18, 2024, with electric vehicle (EV) batteries being the first to be impacted, requiring mandatory carbon footprint disclosure starting from February 18, 2025.

For the calculation of EV battery carbon footprints, the European Commission is expected to publish the official calculation guidelines by February next year. Prior to the formal publication of the regulation, the Joint Research Centre (JRC) of the European Union released the Final Guidelines for Calculating the Carbon Footprint of Electric Vehicle Batteries (hereinafter referred to as the Guidelines) as a research report for the official guidelines. Although this document is not a formal legal text, it serves as an authoritative methodological guide from the EU, referencing the EU Environmental Footprint Calculation Method (EF: Environmental Footprint) and the Battery Product Environmental Footprint Category Rules (PEFCR: Product Environmental Footprint Categories Rules). It offers strong guidance on the implementation of future battery carbon footprint calculation methods in terms of calculation logic, data requirements, and reference standards.

This series will be divided into two parts to explain and analyze the EU's Final Guidelines for Calculating the Carbon Footprint of Electric Vehicle Batteries. We will focus on aspects such as calculation boundaries, cut-off principles, data collection, modeling, and recycling allocation, identifying key points and challenges to help enterprises prepare in advance.

01

Calculation Boundaries and Cut-off/Exclusion Principles

The calculation boundaries outlined in the Guidelines include the raw material acquisition and pre-processing stage (Raw materials acquisition and pre-processing), the manufacturing stage (Manufacturing), the distribution stage (Distribution), and the end-of-life stage (End-of-life). According to the Guidelines and the final regulation, emissions generated during the use phase of the battery do not need to be accounted for.

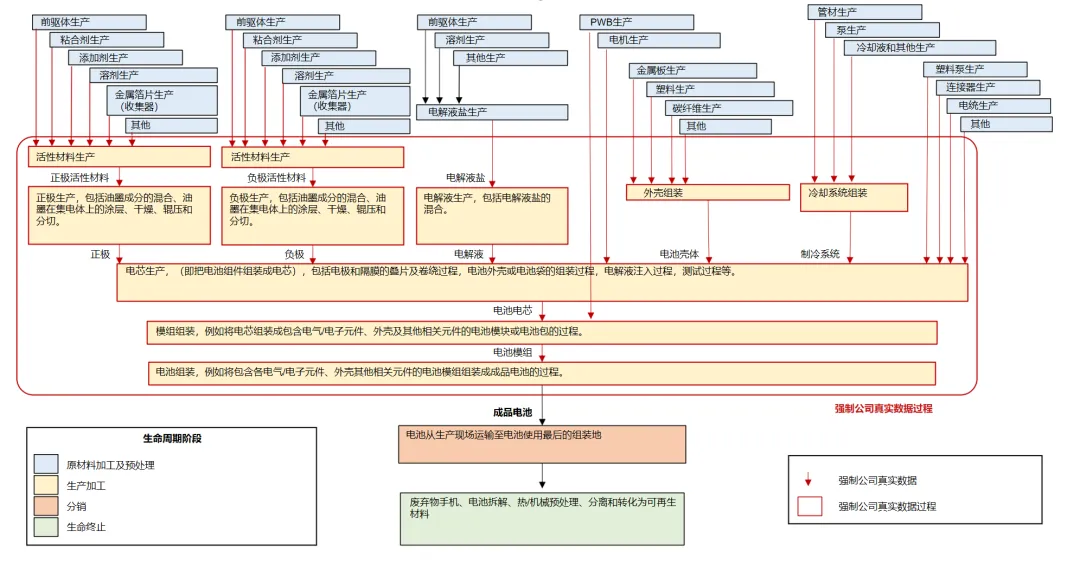

Calculation system boundaries for General Motors' EV battery (EV battery)

/ Raw Material Acquisition and Pre-processing Stage /

This stage includes the extraction of raw materials from the environment, pre-processing (to produce materials suitable for processing), and the transportation of raw materials and semi-finished products. Based on the PEFCR, the Guidelines consider the environmental impacts associated with the production process of battery packaging materials to be minor and exclude them. Similarly, cooling structures that are not placed inside the battery housing or physically connected to it are also excluded.

/ Manufacturing Stage /

The manufacturing stage includes the processing of raw materials into semi-finished products, further processing of semi-finished products, and assembly. The endpoint of this stage is typically the completion of finished product manufacturing and readiness for subsequent distribution and transportation. An EV battery usually consists of multiple cells that undergo additional processing to form a battery pack suitable for use in electric-powered vehicles.

The manufacturing stage of batteries, according to the Guidelines, primarily includes the following processes:

- Production of anode and cathode active materials.

- Anode and cathode production, including mixing ink components, coating ink onto the collector, drying, calendering, and slitting.

- Electrolyte production, including mixing electrolyte salts.

- Shell and cooling system assembly.

- Cell production (i.e., assembling battery components into cells), including stacking and winding electrodes and separators, assembling battery shells or pouches, injecting electrolytes, and testing processes.

- Battery module assembly, such as assembling cells into battery modules or packs containing electrical/electronic components, housings, and other related components.

- Battery assembly, such as assembling battery modules containing various electrical/electronic components, housings, and other related components into finished batteries.

- All transportation processes of final products and intermediate products to the point of use.

For manufacturers whose business scope includes both the production of EV batteries and the installation of EV batteries into devices (such as electric-powered vehicles), the Guidelines suggest that the environmental impacts of energy and material consumption during the installation process are relatively minor compared to the battery manufacturing process and can be neglected.

Additionally, based on the EU Battery Product Environmental Footprint Category Rules (PEFCR for battery), emissions from the production of equipment (capital goods) used in the manufacturing process should also be ignored.

Carbonstop Insights

Overall, the Guidelines set higher requirements for the manufacturing stage of EV batteries compared to other stages. For battery manufacturers, this stage requires particular attention: On one hand, as a stage closely related to the company's production process, the new battery regulation and the calculation guidelines place strict demands on enterprise-specific real data for this stage (see the data collection section), which will affect the data collection for the EV battery manufacturing process and require additional attention from enterprises. On the other hand, as a product stage that companies can directly influence and control, early preparation will significantly benefit the company's data management, energy management, and carbon management.

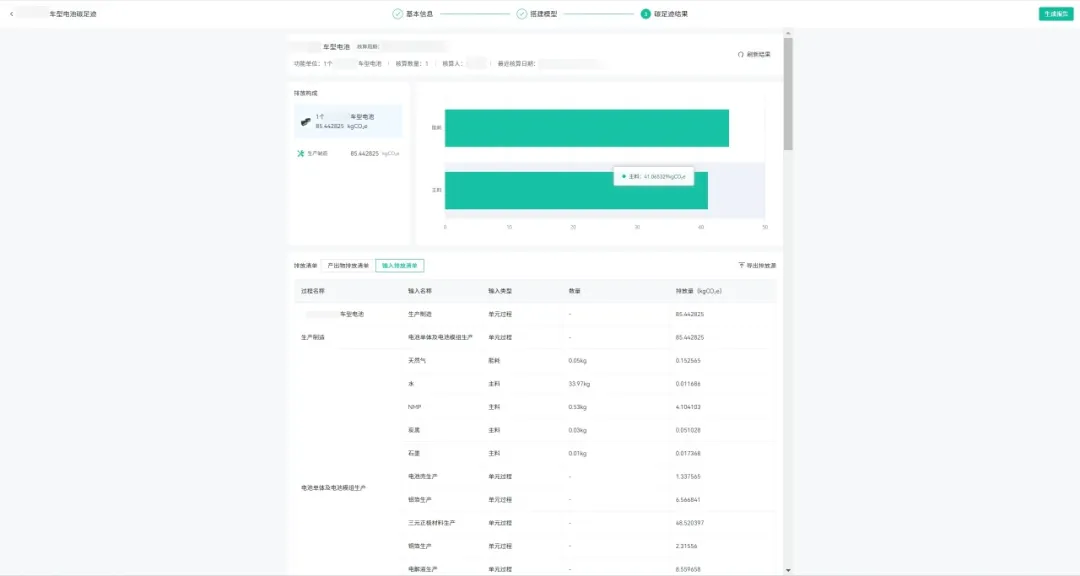

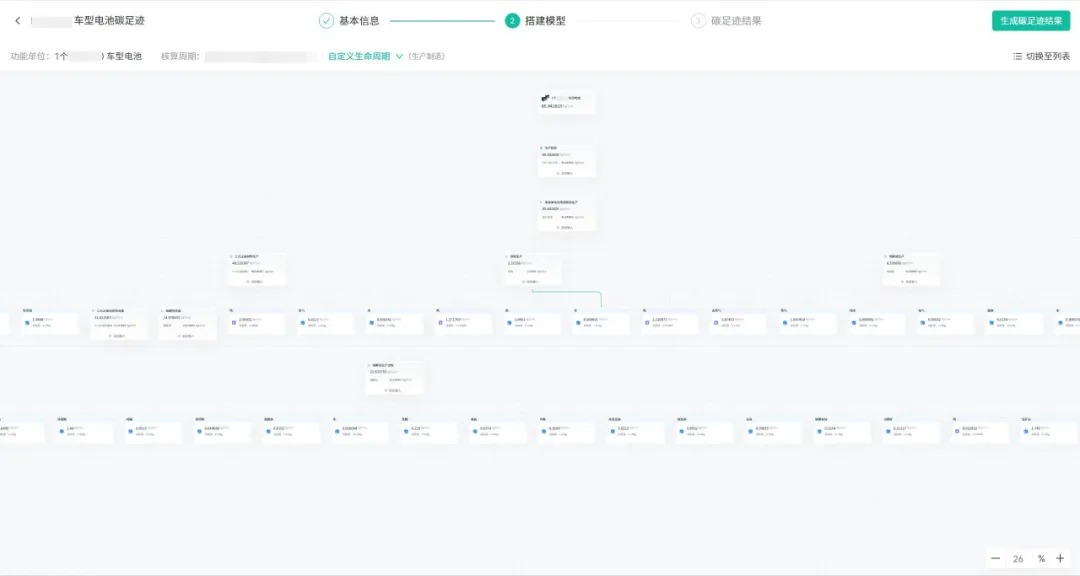

Calculating the carbon footprint of the lithium-ion battery production stage using Carbonstop SaaS model (example)

/ Distribution Stage /

For the distribution stage of the product lifecycle, the Guidelines define the scope as: the transportation of the final battery from the production site to the final assembly site, and the environmental impacts generated during the warehousing and operational processes can be ignored.

/ End-of-Life Stage /

The Guidelines interpret the end-of-life stage of EV battery products as: starting from when the battery is discarded or abandoned by the user until the battery waste materials return to the natural environment as waste products or enter another product lifecycle (as recycled raw materials). Additionally, if other lifecycle stages (such as raw material and processing stages) generate waste, the environmental impacts of subsequent collection and disposal processes should be calculated in the corresponding lifecycle stages, not in the overall product's end-of-life stage.

The Guidelines specify the processes covered in the end-of-life stage as follows:

- Battery waste collection process

- Battery disassembly process

- Thermal or physical pretreatment of waste batteries (such as milling cells)

- Separation and conversion into recycled materials (such as pyrometallurgical and hydrometallurgical treatment processes)

- Energy recovery and disposal

At the same time, the Guidelines stipulate that processes that can be ignored in terms of environmental impact during the end-of-life stage include: battery waste collection processes, battery waste pretreatment processes (including removal from vehicles, discharge, and sorting), battery and component disassembly processes, and transportation processes within the end-of-life stage.

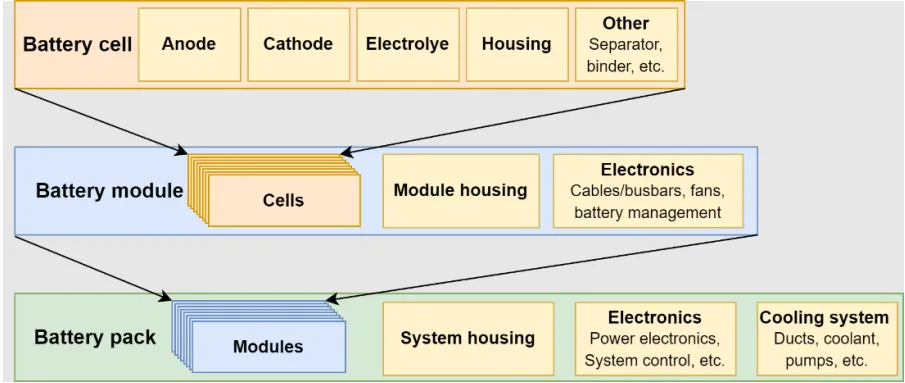

Electric Vehicle Battery System Components / Source: Final Guidelines for Calculating the Carbon Footprint of Electric Vehicle Batteries —— Joint Research Centre (JRC) of the European Union

The guidelines also point out that input items with a mass percentage less than 1% of a system component (such as shell material accounting for less than 1% of the shell weight) can be ignored, but the mass must be added to the input item with the largest carbon footprint in the system to ensure mass balance and adhere to the principle of conservatism.

Carbonstop Insights

As the methodological basis for calculating the carbon footprint of electric vehicle batteries, the guidelines define detailed calculation boundaries and propose reasonable criteria for exclusion. At the same time, the guidelines emphasize the importance of the battery production stage for carbon footprint calculations, urging battery manufacturers to pay close attention. Suppliers can assess their own risks based on the processing stage examples provided in the guidelines and plan ahead.

02

Data Collection and Data Quality Requirements

Data collection is a crucial step in carbon footprint calculations. The guidelines clearly define the requirements for data, dividing the collected data into mandatory enterprise-specific real data and non-mandatory enterprise-specific process data, providing detailed collection requirements and principles for each, along with quality requirements for some data.

/ Requirements for Collecting Mandatory Enterprise-Specific Real Data //

The guidelines define enterprise-specific real data, which includes activity data and elementary flows, and require enterprises to obtain actual data from specific manufacturing equipment used in specific battery processes.

The guidelines stipulate that all process data during the production stage of electric vehicle batteries must be provided as enterprise-specific real data. This stage mainly includes the production of anode and cathode active materials, anode and cathode production, electrolyte production, shell assembly, cooling system assembly, battery production, module assembly, and battery pack assembly. However, it is often difficult for the entity responsible for declaring the carbon footprint of battery products (CFB) to cover all relevant processes within its business scope, so it needs to collect process data from suppliers.

The guidelines suggest the following collection schemes for such mandatory enterprise-specific real data:

Scheme 1

- Suppliers provide all activity data, elementary flows, supporting research materials for the CFB, and all information required for verification to the CFB reporting entity.

Scheme 2

- Suppliers provide enterprise carbon footprint datasets that comply with the CFB standards to the CFB reporting entity. In this case, the CFB reporting entity should ensure that all documents are received by the approval authority when submitting the carbon footprint declaration.

Scheme 3

- Suppliers provide all activity data, elementary flows, supporting research materials for the CFB, and all information required for verification to a third-party organization (such as a data management company). The third-party organization integrates the input data from different companies separately and provides aggregated datasets that comply with the CFB standards and are based on different industrial processes to the CFB reporting entity, ensuring the confidentiality of supply chain information. In this case, the CFB reporting entity, suppliers, and third-party organizations should ensure that the approval authority receives all documents required for verifying the carbon footprint declaration.

From the schemes provided by the guidelines, it can be seen that the CFB ultimately needs to submit process datasets, supporting research materials, and other necessary documents for verification of the battery processing stages to the approval authority. The main differences among the schemes lie in the changes in the entities handling the raw data. Simply put, the methods for enterprises to collect carbon footprint data for battery processing stages are:

- To collect raw data such as activity data and elementary flows from suppliers and aggregate them into datasets themselves;

- To request suppliers to pre-process the data and directly submit datasets;

- To have a third-party data processing agency handle the relevant data processing;

For the concept of "datasets," the guidelines define it as "containing lifecycle information of specific products (or processes, etc.), descriptive metadata, and quantified lifecycle inventory (LCI dataset) or lifecycle impact assessment results (LCIA dataset)." For choosing between LCI and LCIA result datasets, the guidelines do not show a clear preference. However, if choosing to provide an LCI dataset, the LCIA climate impact results must be provided simultaneously, whereas if choosing to provide an LCIA dataset, only the climate impact results need to be provided.

The guidelines have the following requirements for "enterprise-specific real datasets that meet the CFB requirements":

- The model construction must comply with the requirements of this guideline;

- The naming of elementary flows must meet the EU EF3.1 (Developer Environmental Footprint) reference document;

- The naming of process datasets and product processes must follow the ILCD Handbook - Naming and Other Conventions;

- Complete DQR (Data Quality Review, evaluation indicators include technical representativeness TeR, geographical representativeness GeR, and temporal representativeness TiR) and provide the results;

- Include metadata;

- For CFB standard enterprise-specific real datasets describing component products, the system boundary should exclude distribution and end-of-life stages;

- External verification is required;

Regarding metadata, sections 8.2.2 and 8.2.3 of the guidelines detail the contents that need to be included, such as the overall model (details of each lifecycle stage, electricity modeling, allocation, recycling models, etc.), secondary data, situations of cutoff, CFB results (and sub-item results at different stages), and background information about other data.

Carbonstop Insights

The guidelines specify that the establishment of enterprise-specific real datasets must include all known inputs and outputs of the process. It is worth noting that the inputs and outputs of industrial processes do not conflict with the requirements for LCI or LCIA datasets. Enterprises can choose to present the process carbon footprint results using either LCI or LCIA methods, but the collection and provision of activity level data for the process inputs and outputs are necessary.

In addition, enterprise-specific emission data can be based on direct measurements or calculated using enterprise-specific activity level data and corresponding emission factors (for example, fuel consumption in liters and emission factors for vehicles or boilers).

For industries covered by the EU Emissions Trading System, priority should be given to meeting the quantification requirements for relevant processes and greenhouse gases specified in EU Regulation 2018/2066. At the same time, the guidelines allow for reasonable and a certain degree of data processing, such as allocating total consumption of a process or plant based on functional units or reference processes, but all data processing procedures should be clarified in the CFB supporting research documents.

/ Requirements for Collecting Non-Mandatory Enterprise-Specific Real Data /

In addition to the mandatory enterprise-specific process data, the guidelines categorize other processes as non-mandatory for enterprise-specific real data and distinguish between most relevant and non-most relevant processes based on their relevance to the main processes.

For the most relevant processes, the guidelines refer to the Battery PEFCR and related literature, suggesting they should cover the following:

- The production of cathode active material precursors, including: cobalt, nickel, iron, and lithium (metallic or salts).

- The production of anode active material precursors, including: graphite, metallic lithium, hard carbon, silicon.

- The production of electrolyte salts and precursors, including: LiPF6, lithium salts.

- The production of copper, such as in current collectors, busbars, and cables.

- The production of aluminum, such as in current collectors, busbars/cables, and shells.

- The production of steel, such as in shells.

Other processes outside of these are considered non-most relevant processes.

The guidelines also provide specific data collection and modeling requirements for processes that do not require mandatory enterprise-specific real data. For such data, secondary data should be used as the activity data for modeling. When selecting secondary data, the guidelines recommend prioritizing data sets with high technical representativeness, compliance with EF standards, higher DQR, and sourced from the EU Life-Cycle Data Network (LCDN). The guidelines provide detailed principles for the selection and modeling of such secondary data, which are not repeated here.

Carbonstop Insights

From the perspective of data collection, the guidelines require the collection of all enterprise-specific real data for the production stage processes, while allowing the use of secondary data for other processes. However, for data sources, the guidelines favor data from EU-owned databases or databases that comply with EU standards.

The guidelines do not explicitly define the specific tasks of upstream and downstream enterprises in the industrial chain regarding data collection but provide several recommendations as references. For downstream manufacturers, the level of detail of the data provided by upstream suppliers determines the workload and duration of the declaration process. It can be anticipated that how to standardize, accurately, and systematically collect and process supplier data will be a challenge that downstream manufacturers with export needs to the EU must solve.